|

|

Post by digitalbt on May 21, 2011 7:48:32 GMT -6

Hello everyone! I just purchased a wind up phonograph yesterday. (See attached photo) I've been tearing apart record players from early childhood and as an adult have repaired tape decks, turntables, videodisc players, VCR's and recapped a 1953 Muntz television as a hobby. I got paid to repair Library of Congress Blind and Handicapped record players in high school. I have always wanted a wind up phonograph, so my first purchase is a Columbia Grafonola and I paid $100 for it. Good price yes? When you turn the crank, it just turns and turns...feels like nothing is grabbing hold. (Doesn't pop either) I removed the mechanism and discovered it has 3 springs. When you turn the spring barrels directly, it feels like the springs will wind, but whatever they "grip onto" (like the main shaft) isn't gripping. When I removed the main shaft that all the springs attach to, nothing appears to be broke or missing. There's a ton of grease all over everything...the grease doesn't appear to have seized up. What do you guys think? Attachments:

|

|

|

|

Post by phonofreak56 on May 21, 2011 10:09:58 GMT -6

Nice machine and welcome to the forum. From what you described, the spring either detached itself from the winding arbor, or the end is broken off. Good luck with your machine. They get addicting after a while.

Harvey Kravitz

|

|

|

|

Post by eckster on May 21, 2011 20:12:28 GMT -6

Or it could be where the spring fits on the groove could be slightly stretched or bent causing it to slip off the arbour shaft try and send a dissassembled picture of the springs so one can take a closer look at the springs or even the arbour shaft

|

|

|

|

Post by roaring20s on May 21, 2011 21:49:08 GMT -6

|

|

|

|

Post by digitalbt on May 22, 2011 21:00:42 GMT -6

Thank you for the replies and links! So far, I've taken the tone arm off and completely cleaned and disassembled it, lightly sanded and lubricated the base with sewing machine oil and put it back together. The tone arm now moves freely and looks better, although still somewhat tarnished. I can live with it. I replaced the 4 wooden knobs on the front with new polished silver ones...not original, but spruces up the front a bit. Tonight, I completely disassembled the motor and I'm soaking all the parts in degreaser to remove the molasses like oil that was all over everything. I found some spare needles inside the cabinet too, good find! Once I get the motor reassembled, I'll either link a YouTube video or post a photo of the arbour shaft and spring barrels. One of the needle cups was missing from the top and I found a silver "end cap" at Lowes that made a perfect substitution for an open hole.

|

|

|

|

Post by roaring20s on May 22, 2011 21:28:04 GMT -6

|

|

|

|

Post by digitalbt on May 23, 2011 16:16:49 GMT -6

Thank you roaring20s. Understood. There are a few really unique looking needles in the mix also. One of them has a spade (deck of cards) shape on the end. One has a thick base, but a thinner tip. Similar to this one: periodictable.com/Samples/076.1/index.s12.html |

|

|

|

Post by eckster on May 23, 2011 17:05:46 GMT -6

If you have favorite records or some that are really rare it is a good idea to use bamboo or cactus needles it will greatly extend the life of your records even if you religiously replace steel needles everytime you play a record you will eventually lose the sound quality And that molasses like oil you found is partially hardened spring barrel grease. To regrease I use 10 parts vaseline to 2 parts graphite either flaked or powdered which can be obtained either from an auto parts store or Arts and crafts store

|

|

|

|

Post by digitalbt on May 24, 2011 15:51:24 GMT -6

Thanks, eckster. I likely WON'T be playing any records that are valuable on this. In fact, I went by the antique mall last weekend and purchased a few $1 78's just for test purposes.

Last night a light went off in my head and I get how this motor works now! Woohoo! The crank's shaft hook isn't latching on to the spring inside the first barrel. The spring end isn't broke, but it appears to be bent or the grease inside is too sticky to allow the spring to unwind completely. A buddy and I are going to open the cans and regrease them. Thanks for the grease recipe! Any other pre-made grease you'd recommend?

The rest of the motor parts (gears, etc.) are now de-greased and ready for action!

|

|

|

|

Post by eckster on May 24, 2011 19:25:38 GMT -6

|

|

|

|

Post by digitalbt on May 29, 2011 21:04:42 GMT -6

Update: I purchased the graphite powder in tubes and bought Vaseline at Walgreens to make my own grease (Tom would be proud). Getting this motor going also required rubber gloves, work gloves, drill bits, vise grips, a vise, a sheet of green felt, an exacto knife, a glue stick (for the new turntable mat) 2 cans of degreaser spray, countless rags, a blow torch, and a drill. The 3rd spring was broken in half so I hired my friends who are small engine mechanics to assist me in getting the barrels open, springs degreased and regreased, heating up the good half of the broken spring and drilling a new hole for the spring to "catch" onto the shaft "button". (are those called arbor hooks?) We miscalculated the spring directions and so after re-assembly spring #2 and #3's center ends both flipped the other direction and made an S. I spent nearly all day today getting those springs turned back around, removed, reloaded, and like to never got them adjusted so they'd catch on those shaft button things. This was a huge pain. Long story short, it was very fulfilling to finally see that motor work again and play a record. To celebrate, I made a video with my iPhone: www.youtube.com/watch?v=3aMWJ3fpfm0I have a feeling these springs aren't going to hold up. But I hope they do! Thanks again for everyone's help and advice! |

|

|

|

Post by eckster on May 29, 2011 22:32:02 GMT -6

Your welcome that link of the compleat repair guide has a lot of quick fix techniques that i dont follow but it is still quite informative, Remember your play time will be greatly reduced. Is the 3rd spring only half its size or did you reattach the broken ends? If so only give the motor 30 cranks or less do not crank it to its resistance point or the spring will break quicker let me know. You could save the head ache of disassembly again

|

|

|

|

Post by digitalbt on May 30, 2011 7:02:30 GMT -6

eckster: The 3rd spring is only half its size. And I will definitely take your advice on the cranking. It seems to have enough time to play an entire record without cranking to the resistance point. I've been cranking it until it STARTS to feel some resistance. Below is a link to a video I made of the motor before another whole day of work on it again! www.youtube.com/watch?v=21WE-Aj_dv0

|

|

|

|

Post by eckster on May 30, 2011 21:23:02 GMT -6

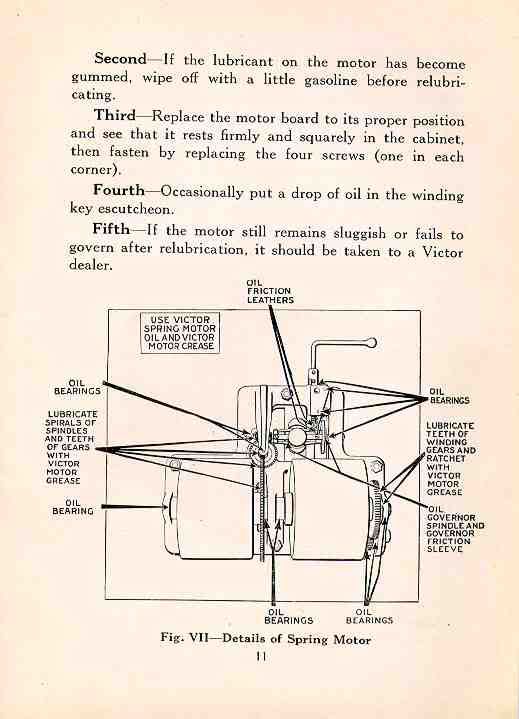

Only use graphite grease for the springs Use pure vaseline for the continuous gear on the governor and turntable gear. Also a dab of grease on the main gear of the spring barrel. (not overkill) OIL not greaseThe governor shaft ends that go into the sleeves that are held by the pinch screws the speed control brake wick and the slider shaft on the governor that holds the weight. OIL and mix a bit of Pure vaseline to the ratchet pawl for the wind crank You want that grease a bit more creamier so the pawl does not stick and cause painful crank kickback or break the spings again, greasing everything atracts dust here are some oiling instructions  Ya it says here to use grease on the ratchet but i dont I would rather much use 3 in 1 machine oil mixed with a bit of vasoline. And dont use gasoline for cleaning there are a lot more healthy solvents nowadays for cleaning |

|

|

|

Post by eckster on May 30, 2011 21:49:10 GMT -6

That tick tick tick noise might be the governor set too tight. You want the continuous gear ( the helix looking one) onthe governor to be perfectly centered with the gear it rides on with the least amount of playYou want the grease to fan out from the center of the continous gear but still have a film of grease in the middle of the helix you may have to raise or lower the the main gear to achieve this if the noise does not go away post another link There is also another method I have.

|

|